How Dust Particle Counters Work

Light scattering occurs when light illuminates air particles. Light scattering depends on particle size, wavelength, refractive index, and light absorption. The intensity of dispersed light by particles grows with particle surface area according to a simple rule. So long as scattered light intensity is quantified, particle size can be inferred. Each particle’s scattered light is relatively feeble, creating a brief light pulse. A photoelectric converter amplifies light pulses to convert them. It’s turned into electric pulses with increased signal amplitude, then amplified and screened by electronic circuits to count many electric pulses. The number of electrical pulses equals the number of particles, and their amplitude equals their size.

Lens group 1 focuses light from the light source into the measuring cavity. Each air particle passing through the measuring cavity once scatters incident light to create a light pulse signal. This light signal is transmitted to the photodetector through lens group 2 and transformed into an electrical pulse signal proportionately. The needed signal is picked out and displayed by the counting system.

What factors need to be considered before choosing a high flow dust particle counter?

The following things should be taken into account:

1) What kind of information is to be gathered? Is this information just marked as “pass” or “fail”? Or is the information kept in a database or spreadsheet?

2) In what kind of setting will the particle counter be used? Will it be used to count particles on a regular basis in an ISO Class 3 clean room, or will it be used to check flow in a critical process?

3) Can this particle counter be used to certify clean rooms and do tests in different places?

4) Does the operator keep the dust particle counter nearby, on a critical process bench or on a rolling cart that can be moved?

5) Will the dust particle counter be used to keep track of particles in a cleanroom in a dynamic way all the time? Is the particle counter meant to be linked to a system for monitoring the environment?

6) Sensitivity: Small particles can be found.

7) Counting efficiency: the ratio of how many particles were counted to how many there really were. Use a more sensitive instrument with a 100 percent counting efficiency at the small particle size of the instrument being tested to measure the true particle concentration. A properly made instrument should be able to count 50 percent of the time.

8) Zero count level or false count rate: The number of falsely reported particles using filtered air at an optimal flow rate for a certain amount of time. This correct report shows how many particles there are every 5 minutes. (The rate of 0s should be less than 1 every 5 minutes if that’s what you want.)

9) Flow Rate: This is the amount of air going through the particle counter. Most of the time, this is measured in cubic feet per minute. 1.0cfm and 0.1cfm are two common flow rates. The pump that pulls air in and the particle counter get bigger as the flow gets bigger. 10. Channels: This is the number of “bins” the particles are put into based on their calculated sizes. The size of a channel is measured in microns. For instance, you might have a particle counter with six channels. This means that particles can be counted and put into groups in 6 ways. Examples of channels are: 0.1um, 0.2um, 0.3um, 0.5um, 1.0um, 5.0um.

Most of the time, other factors are used to choose the small size. This is an important thing to think about, but there are other things to think about as well.

How to choose a particle counter?

How to choose a particle counter among the numerous available depends on its technical parameters, performance, and accessories. Measures particle size, light source, flow rate, display mode, counting mode, alert level, power supply, etc.

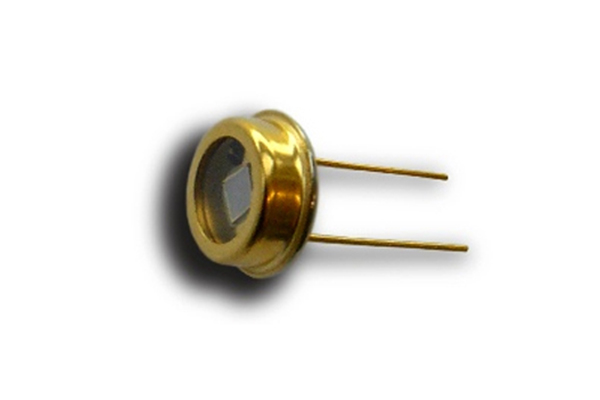

Particle size measurement directly affects the instrument’s conversion sensitivity. Signal voltage and particle size affect conversion sensitivity. The laser dust particle counter’s photoelectric technology converts particles of varying sizes into electrical pulse signals of varied amplitudes (voltages).

Particle size and pulse voltage are proportional. The laser dust particle counter monitors the number of particles over a specific size, and its internal circuit counts pulses above a given voltage. When buying, evaluate the internal circuit’s performance, or conversion sensitivity.

The particle counter’s light source also affects its performance. A stable, long-lasting, interference-free light source is needed. Ordinary and laser light sources power the laser dust particle counter. Iodized tungsten lamps are huge, hot, and short-lived. Start-up requires preheating. Lasers are tiny, stable, and long-lasting. It’s combined with the detection cavity and photodetector to make a sensor. HeNe and laser diode lasers are common. Using a common light source, the laser dust particle counter has a low response to particles smaller than 0.3 m, and the signal amplitude is about the same as the noise amplitude, making it hard to find the signal.

These instruments have a 0.3m channel, but they only measure particles over 0.5m. The laser’s monochromaticity is good, and the light energy is focused and stable, so the laser dust particle counter has a high signal-to-noise ratio. Some of these instruments can detect particles as small as 0.1 m.

An internal air pump controls sampling flow for a desktop particle counter. The air pump needs low noise, low vibration, and stable airflow to perform efficiently. Display modes include LCD and LED digital tubes. Liquid crystal display instruments are generally more expensive. Counting modes vary by brand. Fluck983 adds an audio mode that alerts the user when the preset concentration value is exceeded. COOLUX particle counters use differential technology to count particles between two sizes that have been measured (detection channels that are next to each other).

Handheld particle counters are more portable. Included are an AC adapter, a zero count filter, a portable protective case, a rechargeable battery, communication software, a communication cable, etc. Since the handheld has no built-in printer, a mini-printer or a printing cable are needed.

How to use a laser dust particle counter to measure more accurate data

The laser dust particle counter measures the number and size distribution of dust particles per unit volume in a clean environment, evaluating air quality. Common laser Dust Particle Counters include light scattering types (DAPC) and condensed core types (CNC), which measure smaller particles. After being converted by the laser dust particle counter’s photoelectric system, different-sized particles emit electrical pulse signals of varied amplitudes (voltages). Higher pulse voltage for bigger particles. Different people may measure results differently. The company constructs a dust-free workshop for production. How to quantify dust?

1) Test at one test point.

2) A maximum of two people are allowed at a test site to prevent the stability of the test data from being affected by the personnel.

3) You can choose to use the average mode of the laser dust particle counter to test three times at a test point to obtain the average value, which will make the test data more stable and accurate.

4) Testers must wear clean clothes, caps, etc., as instructed to keep outside factors from affecting the results. During the test, people should not walk, talk, shake clothes, etc., which will change the air flow near the test point and make the test results less stable. Avoid the high-efficiency air outlet because the air at the return air outlet is pretty clean, which will throw off the test results; Stay away from the humidifier because it will make the air near the test point more humid, which is too much for the laser dust particle counter to measure. It sometimes didn’t pass tests normally;

5) 5 decimeters means that the distance between the tester and the particle counter is 50 cm away.

FAQ:

Can Dust Particle Counters Detect Microorganisms?

There are a lot of things, like microorganisms, dust particles, and bacterial microorganisms, that need to be tested in the clean room. This means that a lot of testing tools are needed. Because of this, some people wonder if a dust particle counter could be used to find microorganisms in the air. A lot of money can be saved by counting the number of particles and microorganisms. At the moment, though, there isn’t a dust particle counter that can find microorganisms. The dust particle counter is just a tool for measuring the size and number of dust particles in the air.

There are also special tools for finding microorganisms, like the planktonic bacteria sampler, which can count the number of bacteria in a given volume of air. The collection port is made with more than 300 tiny holes, which reduces the chance that dust and bacteria will mix together during the sampling process. This also makes it easier to count and assign points. The body sampling head can be used for different kinds of sampling.

How to set the dust particle counter’s accuracy?

The dust particle counter mostly looks at the size and distribution of dust particles in the area to decide how clean it is. Most of the time, a dust particle counter with an accuracy of 0.5um can meet the needs of a clean room with a cleanliness level of between 100 and 100,000. You can, of course, choose a dust particle counter with a size of 0.3um or even smaller if you have the money. Users should buy the dust particle counter based on how much they need it to avoid wasting money.