Advantages and disadvantages of various methods of particle size

Sieving method: Advantages: simple, intuitive operation, low equipment cost; typically used for samples longer than 40 m. Disadvantages: It cannot be utilized for samples as fine as 40 m; the results are heavily influenced by human variables and mesh deformation.

Microscopy: Advantages: the ability to perform simple, straightforward morphological analysis. Disadvantages: Slow speed, inadequate representation, and the inability to analyze ultrafine particles.

Settlement method (including gravity settling and centrifugal settling): Advantages: ease of operation, continuous operation of the instrument, low cost, good accuracy and repeatability, and a wide test range. Disadvantage: longer testing time.

Resistance method: Advantages: simple operation, measurement of total number of particles, clear equivalent idea, fast speed, and good accuracy. Disadvantages: The test range is limited, the small holes are readily clogged by debris, and the medium must have rigorous conductivity properties.

Electron microscopy: Advantages: the ability to test ultrafine particles and even nanoparticles with excellent resolution. Disadvantages: small sample size, poor representativeness, and pricey instruments. Disadvantage: Reduced resolution.

Breathing method: Advantages: The instrument is inexpensive, the sample does not need to be scattered, and the magnetic substance powder may be measured. Disadvantages: The particle size distribution cannot be measured, and only the average particle size value may be obtained.

Laser method: Advantages: ease of operation, fast test speed, a vast test range, outstanding reproducibility and accuracy, and the ability to do both online and dry measurements. Disadvantages: The distribution model has a large impact on the outcomes, and the instrument is expensive.

The fundamental design of a Laser particle size analyzer

The Laser particle size analyzer‘s construction varies widely depending on the application, but the main structure is essentially the same. System construction.

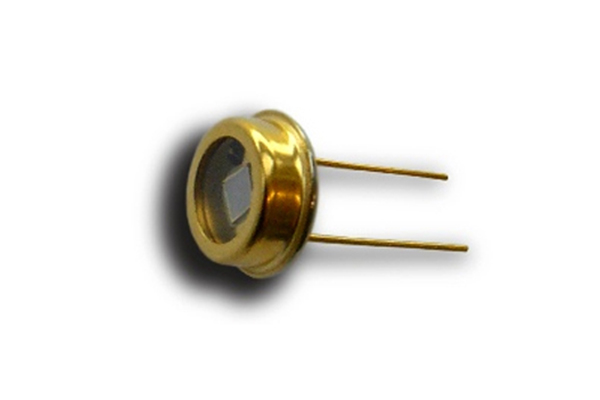

The optical path system and the data processing system are the two main components of the Laser particle size analyzer. The optical path system mostly influences measurement range, while the data processing system primarily influences result accuracy. The data processing system contains signal filtering, extraction, and inversion techniques. The optical system consists primarily of a laser, a spatial filtering-quasi-beam expander system, a Fourier transform lens, a sample circulation system, and a multi-element photo detection array.

Laser particle size analyzer measurement principle

The light scattering principle is used by the Laser particle size analyzer to measure the particle size distribution of the powder sample, which uses the amplitude, phase, and polarization state of the scattered light, as well as other characteristics related to the size and refractive index of the scattered particles after the light is scattered.

Difference between dry and wet Laser particle size analyzer

There are two ways to test with a Laser particle size analyzer: the dry method and the wet method. The dry method uses air as the dispersion medium and turbulent dispersion to fully disperse sample particles, which are subsequently tested in an optical path system. The wet approach adds the sample to a dispersion medium like water or ethanol, then passes it via an optical path system to calculate particle size distribution. Different dispersion media affect dry and wet test outcomes.

Wet or liquid dispersion technologies are replacing dry dispersed particle size determination. Using a dry Laser particle size analyzer to determine particle size offers advantages.

1) If the material is processed and synthesized in a dry state, the particle size determined by the dry method is more representative than the wet method;

2) For some materials, dry method is the choice, because these materials will dissolve in common dispersants or the particle size will change due to hydration after dispersion;

3) In general, dry assay is faster than wet assay, and more samples can be assayed in a short time. Particularly useful for obtaining reproducible results for crude or polydisperse samples.

Not every laser particle size sample is dry-determinable. Very fine or viscous samples may be better for wet measurements since surfactants or other dispersants may be needed for complete and reproducible dispersion. Due to its destructive nature, dry dispersion may not be suited for fragile samples. The dry approach can quantify small sample volumes while the wet method is more reproducible.

How to choose a Laser particle size analyzer?

Because small particles scatter light at a wide angle, usually only particles bigger than 0.5 microns that scatter light at an angle of up to 45 degrees can be seen. So, how do you find small particles, get around the fact that they scatter light poorly, and choose the right Laser particle size analyzer? The performance of a Laser particle size analyzer will depend on the following things.

• Particle size measurement range

Wide range of particle sizes, so it can be used for a lot of different things. Not only should you look at the range of its instrument parameters, but you should also look at how small particle scattering (0.5 m) outside of the main detector area is picked up.

A good way to make sure that background subtraction is always the same is to test the whole range directly. When tests from different methods are mixed together and then put on a map by a computer, there will be mistakes.

• Laser light source

Most of the time, a 2 mW laser is used. If the power is too low, the amount of light that gets scattered will be low, which will make the sensitivity low. A gas light source is also more stable and has a shorter wavelength than a solid light source.

Detector Because the light intensity gets weaker as the radius of the laser diffraction halo gets bigger, it’s easy for the signal-to-noise ratio of small particles to drop and for them to be missed. The distribution of small particle detection can show how good the instrument is. Detectors have gone through several stages, such as being round, half-round, and fan-shaped.

• Malvern’s new generation of detectors

The non-uniform cross-arranged three-dimensional sector detection system has a high actual resolution and no signal dead zone. This is equivalent to 175 in a ring or cross star arrangement and 93 in a semicircular arrangement, giving a direct detection angle of up to 135 degrees.

• Number of channels

In a Laser particle size analyzer, the number of light-receiving areas on the detector is used instead of a “channel” like in a counter. It has an optimization value both in theory and in real life: too little: not enough scattered light received, so accuracy is bad; too much: too sensitive, so it’s hard to get the same results over and over.

Some manufacturers use more channels to meet the requirements for sensitivity in order to lose the reproducibility and make up for the slow sampling speed. So, this kind of measuring time is either 20 seconds or more than 1 minute.

•To use the full Mie theory or not

The Mie dispersion theory is very complicated and requires a lot of data processing. Because of this, some manufacturers ignore the optical properties of the particles themselves, such as refraction and absorption, and instead use an approximation of the Mie theory, which limits its use and makes it more likely that something will be missed.

Accuracy and Repeatability Metrics

The higher the better. Using NIST standard particle detection.

- Stability

The stability of the Laser particle size analyzer includes the stability of the optical path and the stability of the dispersion system and the influence of the surrounding environment. Generally speaking, gas lasers are used and optical platforms are used to help stabilize the optical path. Internal heat-generating components (such as 50-watt tungsten lamps) will affect the surrounding environment of the light path.

- Scan speed

Fast scanning speeds make data more accurate, stable, and repeatable. Different manufacturers’ instruments scan at different speeds, from 1 to 1000 scans per second. In general, the accuracy of the average results is better when there are more cyclic scanning tests, so the higher the speed, the better. The jet dry method and the spray require the higher the speed, the better. The free fall dry method is not fast, but the speed is also better because the particles only pass through the sample area once.

Speed is also affected by how many samples the user has to process every day. Automatic centering, automatic correction, and no need to change lenses.

Easy to use and keep up

Maintenance has a direct effect on how well the instrument works and how long it lasts. Whether it is easy to take apart and clean: There are two parts to the particle size analyzer: the main engine and the disperser. The sample flow cell always needs to be cleaned, but how often it needs to be cleaned depends on the sample. Instruments that combine the main unit and the disperser into one often put the sample cell deep inside the instrument, where it is hard to get to and where the optical path system is easy to damage.

Wet process

The key to making sure the analysis results are repeatable is if it has physical dispersion functions like ultrasonic and stirring, and if the ultrasonic power and stirring speed can be changed at any time.

Dry method

Is it a closed measurement? Is it easy to spread the sample? If not, do you choose a jet disperser? The 300 m/s airflow that hits the sample is needed to make sure that the sample can be spread out enough to get real analysis results.

Laser particle size analyzer price

Laser particle size analyzers from different companies cost different amounts because of how they are set up, how accurate they are, what they can do, and other factors. At the moment, Laser particle size analyzers cost between $10,000 and $60,000. In general, the price goes up and the accuracy of the average results goes up with the number of loop scan tests.

How to choose the shading ratio when testing the Laser particle size analyzer

A sizing ratio is the sample suspension concentration when tested using a Laser particle size analyzer. The Laser particle size analyzer‘s particle size testing technique requires the correct shading ratio. Whether a concentration is appropriate depends on its accuracy and representativeness.

Laser particle size analyzers measure sample concentration based on the assumption that sample particles don’t secondary scatter. The distance between suspended or airborne particles is 3 times their diameter. In the real particle size test, the shading ratio is adjusted to ensure no secondary scattering between particles. The shading ratio shouldn’t be over 50% or too low (less than 5 percent).

If the shading ratio is too high, the particle concentration will be too high, secondary scattering will occur, and the measurement error will increase; if it’s too low, the sample will be too dark. The medium’s particle concentration, quantity of particles, representativeness, and test results may be invalid. To get the correct measurement, the shading ratio must be tested multiple times.

Result

For thick samples, the shading ratio can be 2030%, and it can be 1025% under typical conditions; for ultra-fine samples, the shading ratio can be reduced, but generally isn’t. More than 40% are empirical values collected through tests, but it’s required to continually experiment to get the shading ratio according to the sample test.