When it comes to cutting-edge technology in manufacturing and fabrication industries, fiber laser cutting machines have emerged as a game-changer. Offering unparalleled precision and efficiency, these machines have become indispensable for businesses worldwide. This comprehensive guide will delve into the world of fiber laser cutting machines, covering everything from their basic functionality to their wide-ranging applications and benefits.

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is a state-of-the-art piece of equipment that utilizes a highly focused beam of light to cut, engrave, or etch various materials. At the heart of this technology is the fiber laser, a type of laser that generates light by using an optical fiber as the active medium. This innovative technology offers several advantages over traditional cutting methods, such as higher precision, faster speeds, and lower energy consumption.

Understanding the Components of a Fiber Laser Cutting Machine

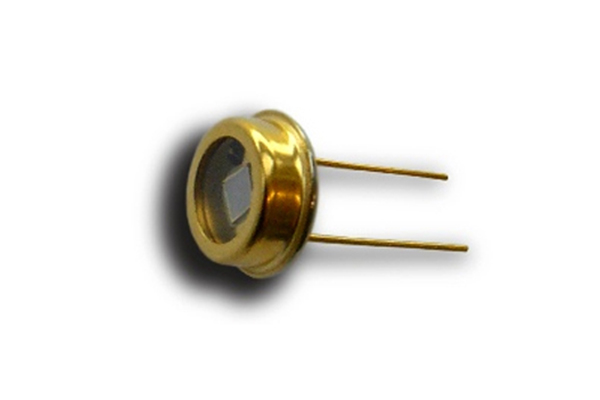

Fiber Laser Source

The fiber laser source is the central component of the cutting machine. It generates the high-powered laser beam necessary for cutting through materials. By utilizing an optical fiber, the laser source can achieve greater efficiency and beam quality than other types of lasers, such as CO2 or Nd:YAG lasers.

Cutting Head

The cutting head is the component responsible for focusing the laser beam onto the material being cut. It contains lenses and mirrors that direct and focus the laser light, ensuring a precise cut. Cutting heads often include features such as autofocus and height sensing to maintain optimal cutting conditions.

CNC Controller

The CNC (computer numerical control) controller is the “brain” of the fiber laser cutting machine. It interprets and executes the cutting program, guiding the machine’s movements and controlling various settings such as laser power and cutting speed. The controller ensures that the machine follows the desired cutting path with high accuracy.

Advantages of Fiber Laser Cutting Machines

Fiber laser cutting machines offer numerous benefits over traditional cutting methods, making them a popular choice for many industries. Some of these advantages include:

• Increased precision: Fiber lasers have a smaller spot size and superior beam quality, allowing for more precise cuts and intricate designs.

• Faster cutting speeds: The high-power density of fiber lasers allows them to cut materials at a faster rate than other laser types or traditional cutting methods.

• Lower energy consumption: Fiber lasers are more energy-efficient than other types of lasers, resulting in lower operating costs.

• Greater versatility: Fiber laser cutting machines can cut a wide range of materials, including metals, plastics, and ceramics.

• Reduced maintenance: Fiber lasers have fewer moving parts and require less maintenance than other laser types, making them more reliable and cost-effective over time.

Applications of Fiber Laser Cutting Machines

Fiber laser cutting machines have become essential tools in a variety of industries due to their precision, speed, and versatility. Some common applications include:

Manufacturing and Fabrication

In manufacturing and fabrication, fiber laser cutting machines are used for creating parts and components with high precision and intricate detailing. They are particularly well-suited for working with metals, such as stainless steel, aluminum, and brass.

Automotive Industry

The automotive industry relies on fiber laser cutting machines for cutting and shaping metal parts, such as body panels, engine components, and exhaust systems. The machines’ speed and accuracy make them ideal for mass production.

Aerospace and Defense

Fiber laser cutting machines play a crucial role in the aerospace and defense industries, where precision and reliability are of utmost importance. They are used for cutting and engraving components for aircraft, satellites, and military equipment.

Electronics and Semiconductor Manufacturing

In the electronics and semiconductor industries, fiber laser cutting machines are employed to create components with extreme precision and accuracy. These machines can work with materials such as silicon wafers, circuit boards, and other delicate components, ensuring a high level of quality control and reducing waste.

Medical Device Manufacturing

The medical device manufacturing sector also benefits from fiber laser cutting machines. They are used to create intricate parts for medical equipment, surgical instruments, and implants. The machines’ precision and ability to work with various materials make them indispensable for producing high-quality medical devices.

Jewelry and Art

Fiber laser cutting machines have revolutionized the jewelry and art industries by allowing for the creation of intricate designs and patterns with unparalleled precision. Jewelers can now cut and engrave precious metals with ease, while artists can create detailed sculptures and decorative pieces from various materials.

Choosing the Right Fiber Laser Cutting Machine

When selecting a fiber laser cutting machine, several factors should be considered to ensure the best fit for your specific needs and requirements. These factors include:

• Cutting capacity: Consider the types and thicknesses of materials you will be working with to determine the appropriate cutting capacity of the machine.

• Machine size and workspace requirements: Assess the available space in your facility and the machine’s dimensions to ensure it will fit comfortably in your workspace.

• Software compatibility: Verify that the CNC controller and cutting software are compatible with your existing systems and workflows.

• Ease of use: Evaluate the machine’s user interface and ease of operation to ensure it will be manageable for your team.

• Budget: Compare the costs of different fiber laser cutting machines, keeping in mind that the initial investment may be offset by long-term savings on energy and maintenance.

Conclusion

Fiber laser cutting machines have transformed the way we approach cutting, engraving, and etching in various industries. Their precision, speed, and versatility make them an invaluable asset for businesses looking to stay competitive in today’s fast-paced world. By understanding the components, advantages, and applications of fiber laser cutting machines, as well as considering the factors when choosing the right machine for your needs, you can harness the power of this cutting-edge technology and elevate your business to new heights.