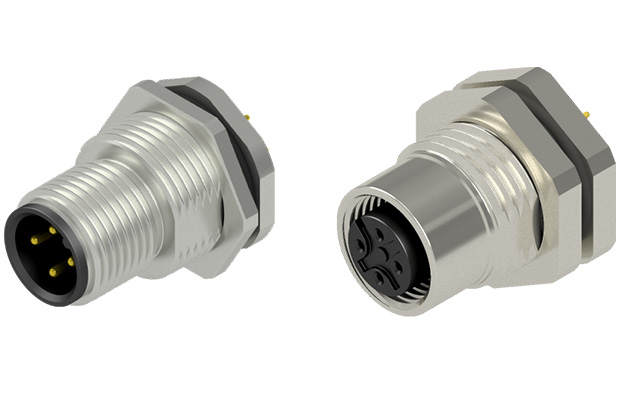

To connect sensing, actuating, and other components (fieldbus and otherwise) to controls and other systems in automated machinery, M12 connectors, a common round cable-termination option, are widely used in industrial, mobile robot, and even consumer-grade designs.

Keep reading, let’s dive into the word of M12.

What Are M12 Circular Connectors?

Compact, tough, and dependable power, signal, and data connections are required in industrial automation and other harsh environment applications, which is why M12 connectors, a type of metric circular connector, are used.

The M12 is one of the industrial market’s most frequently specified connectors and is regarded as the connectivity hub for IIoT systems.

Design Notes

- Standards The IEC 61076-2-101:2012 standard for M12 connectors. The 2003 release of the initial IEC standard is currently in its third revision. IEC 61076-2-010;2021, a new push-pull M12 standard, was published in 2021.

- Coding M-family circular connectors come in a variety of coding options that specify pin counts and configurations in order to prevent mismating. M12s are available in the following configurations: A (3-17 poles), B (2, 4, or 5 poles; primarily used on Profibus and Interbus applications), C (3 to 6 poles; includes a dual keyway to prevent mismating), D (4-poles; standard on Ethernet, ProfiNet, and EtherCat field devices and industrial CAT5e cables), K (5 poles [4+PE]; rated up to 630VAC/DC), L (4 poles or 5 pole

- Cable Considerations With Cat5e and Cat6A cable types, M12 connectors are frequently employed.

- Current Rating Up to 16V

- Mounting Options M12s can be mounted using wave soldering, through-hole, and surface mount techniques.

Review of the M12 Standard

In 1982, M12 connectors were first offered in a non-standard 7⁄8 in size. three-pin connector for a handful of applications. The coupling nut, which is a housing on the cable end that is axially locked to the cable end but allowed to freely spin, was the special feature of the connector and is still in most cases. This allows it to screw onto the corresponding male or female fastener geometry on the receptacle side.

For use with sensors and actuators, the connector was initially standardized by IEC 61076-2-101.

The standard then developed over the following years to include two smaller formats for use with actuators as well as PLCs, switches, and I/O. It also defined a number of M12 codes (detailing pin geometry and function variations). These include M5 connectors and M8 connectors, both of which are defined by IEC 61076-2-104 and have fastener diameters of 8 mm and 5 mm, respectively.

One of the biggest updates to the standard in a long time is found in the most recent version of IEC 61076-2-010 (2020): the inclusion of support for and official definitions of push-pull connections. Molex, CONEC, Weidmüller, Phoenix Contact, and HARTING are among the cable companies that contributed to the development of the standard. The main strengths of push-pull M12 connections are:

- How they dramatically reduce assembly time (by eliminating the need for screwing down nuts and verifying the applied torque)

- the method by which they create connections that are smaller than conventional M12 connectors.

Another Connector Option

The miniature-DIN connector, which is used in communications and industrial HMI peripherals, should not be confused with the M12 push-pull option. Here, DIN stands for the Deutsches Institut für Normung — the governing standards organization that defines the structure and connections within these cable terminals.

After assembly, they rely on an interference fit (friction) between a sleeve on the cable end to keep the plug in the outlet. In order to avoid accidental misconnections with mini-DIN cables that have a similar appearance, these 9.5 mm (3/8 in.) mini-DIN connectors have pin arrays with three, four, five, six, seven, eight, or nine electrical connectors. To aid the assembler and facilitate installation, suppliers frequently add their own proprietary color coding to the cable end and machine-side receptacle. This helps the assembler align the two connection halves.

There are specific uses for which M12 and mini-DIN connectors both excel. However, there are more non-standard mini-DIN connectors available today than ever before, which can lead to both confusion and more design freedom.

In addition, quick connection and disconnection are possible thanks to the interference fit of the mini-DIN securement sleeve. The M12 connector’s screw attachment, in contrast, requires a little more time to assemble but is by nature more secure.

FAQs

What Does M12 Mean in a Cable?

M12 connectors are circular connectors with a 12-mm locking thread used for sensors, actuators, Fieldbus and industrial Ethernet, primarily in factory automation applications. They are ideal for corrosive and washdown environments and frequently have ratings of IP65, IP68, and IP69K.

What is the Difference Between M8 and M12 Connector?

M12 connectors come in 3-, 4-, 5-, 6-, 8-, and 12-pin styles. They are particularly well-suited to harsh environments where corrosion and washdown may occur because they typically have IP65, IP68, and IP69K ratings. The M8 connector is used specifically with industrial sensors.

Are All M12 Connectors Interchangeable?

One of the most widely used industrial connector options on the market is the M12 connector. They are part of an IEC specification that ensures all A-Code connectors are interchangeable with each other.

Are M12 Connectors Standard?

Standards M12 connectors are the IEC 61076-2-101:2012 standard. Currently in its third revision, the initial IEC standard was released in 2003.